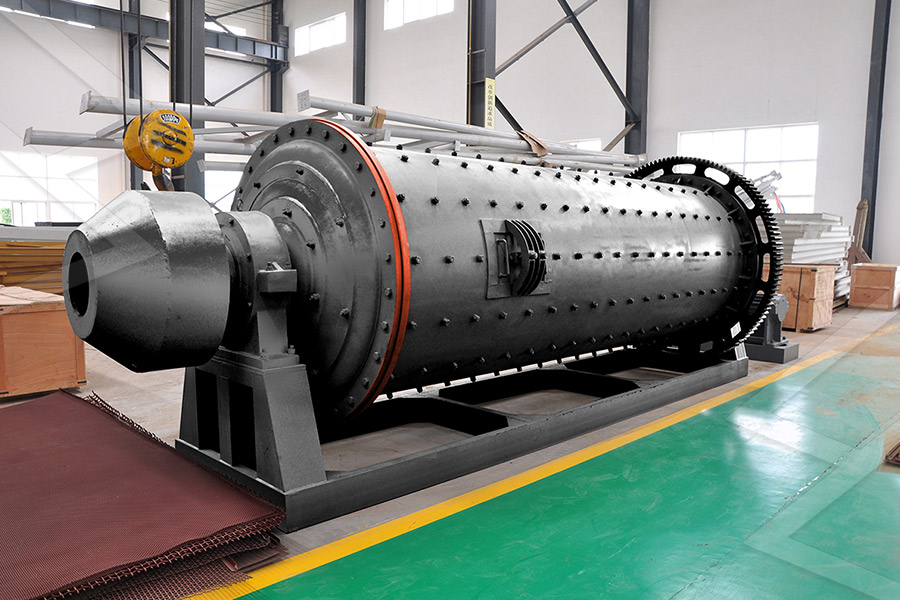

Wet Ball Grinding Mill With High Efficiency Exports To Russia

.jpg)

Ball Mills 46 Manufacturers, Traders Suppliers

5 天之前 Wetmilling technology has been revolutionised by WAB with the development of its horizontal agitator bead mill: It allows very fine particle distributions down to nanometre size to HZE manufacture standard wet ball mills with high efficiency, low energy consumption, stability and reliability for grinding minerals of precious metals, base metals and nonmetal It can also Ball Mill MILLS PRODUCTS Mineral Processing Equipment The GRINDER MILL GMCE is highimpact mill, used to transform semolina into flour It can be used to reduce the size of other shredded materials such as cereals or legumes, in particular Wet grinding mill, Wet grinding grinding system All Highefficiency wet ball mills represent the cutting edge of ball mill technology, combining innovative design features with advanced materials to deliver superior performance These The Superiority of HighEfficiency Wet Ball Mills

.jpg)

THE REVOLUTION IN ULTRAFINE GRINDING RETSCH

• The Planetary Ball mill required a net grinding time of 30 min with an additional 25 hours for cooling breaks • Time saving of almost 3 hours in the Emax thanks to the more efficient functional6 天之前 Dry ball mills are suitable for hard materials like silica sand, quartz, marble, and cement clinker Wet ball mill: Grinds materials into a slurry with a specific concentration, typically 60%–70% Wet ball mills are commonly used Highquality Ball Mill with Low price for Kinds of 5 天之前 PBM 14 planetary ball mill is designed for fine grinding of materials of different hardness in batch mode The grinding can be performed dry or wet The mill is produced by Planetary ball mill VIBROTECHNIKFind the latest exports, imports and tariffs for Balls, iron/steel, forged/stamped for grinding mills trade in Russia 🚢 Download Company Level Data 📦 cross Menu menuBalls, iron/steel, forged/stamped for grinding mills in Russia

.jpg)

Metalloinvest launches production of grinding balls at OEMK

2020年10月12日 Grinding balls are used for ore crushing in ball mills at mining and processing enterprises Russiabased leading steel producer Metalloinvest has announced the launch of 2017年7月3日 Batch Ball Mill Grinding Capacities and efficiencies in wet and dry ball milling at different speeds and ore charges have been discussed in the foregoing pages The results are summarized in table 16, which shows that in both capacity and efficiency grinding was at its best with small ore charges and high speedWet Grinding VS Dry Ball Mill Grinding 911Metallurgist2024年11月11日 In evaluating ore grinding energy consumption using the Bond ball mill work index, discrepancies were identified As a result, an investigation into the determination method of Hou Ying (HY) wet ball milling work index (WHY) for Gongchangling magnetite ore was conducted to determine the correlation between WHY and grinding energy consumption at varying Exploring the Link between HY Wet Ball Mill Work Index and Grinding Figure 4 CMM Ball Mill Feed Machine Grinding Rates With and Without Fines (9% Moisture) Thus, Functional Performance Analysis of the highpressure, opencircuit piston press testing provided the major discovery, and also quantified, that grinding efficiency on REPLACEMENT OF WET BALL MILLING WITH HIGH

.jpg)

Replacement of Wet Ball Milling with HighPressure Grinding

2023年11月28日 In response to the Natural Resources Canada “Crush It Challenge,” Corem partnered with the University of British Columbia and led a project to develop and demonstrate the use of highpressure grinding to replace the workhorse of the industry, wet ball milling Two plant case studies, a small tonnage gold recovery operation and a large tonnage copper recovery 2024年11月29日 Because the granularity of first stage ball mill is large, the impact force is great, and the wear is serious, so the magnetic liner is generally only suitable for the second stage ball mill Grinding medium of ball mill The grinding medium is essential for the ball mill, and the consumption is very largeHigh Efficiency China Stone Grinder Machine Ball Mill Its robust construction and highspeed capabilities ensure reliable and consistent performance in achieving desired particle sizes Our ball mill grinder's efficiency lies in its ability to convert coarse particles into a uniform, fine powder, making it essential equipment for material refinement and preparation across various industrial Ball Mill Grinder Wet Dry Grinding Ball Mill Labotronics2024年12月12日 In this paper, a new grinding method utilizing impellerdriven particle motions was proposed A discrete element kinetic model for simulating the grinding process of SiO 2 material was established Through the quantitative analysis of energy conversion during grinding, the kinetic energy of particles, the kinetic energy of materials, and the energy consumed by Improving grinding efficiency and performance of new impeller type ball

.jpg)

How To Optimize Wet Grinding Ball Mill Performance Wet Ball Mill

2023年12月14日 A wet grinding ball mill is a grinding process using a liquid suspension or slurry, providing efficient and effective particle size reduction in wet conditions Skip to content HOME ABOUT US BALL MILL PRODUCTS Close BALL MILL PRODUCTS Open BALL MILL PRODUCTS; BENEFICIATION EQUIPMENT 2024年4月24日 A ball mill is a crucial type of grinding machine widely employed in various industries for size reduction and material processing So, what is a ball mill? It consists of rotating cylinders filled with grinding balls, which are typically made of steel or ceramicAs the cylinder rotates, the grinding balls collide with the materials, creating both impact and shear forces that What is a Ball Mill? Exploring the Uses and Functionality of Ball Mill 2024年9月15日 Wet grinding ball mills are an essential tool in the industrial sector for processing a wide range of materials These mills are designed to grind and mix materials by using rotating balls that are immersed in a liquid medium, typically wa The mills are energyefficient, have a high capacity, and offer easy control of temperature and pH Wet grinding ball mills: An industrial perspective NEWS2021年5月1日 A ball mill is a type of heavy mechanical equipment that relies on its own rotation to drive the steel balls inside to impact and grind materials with high reliability However, the ball mill has the disadvantages of low working efficiency and high energyconsumptionA method to identify wet ball mill’s load based on

.jpg)

China Wet Ball Mills, Wet Ball Mills Wholesale,

China Wet Ball Mills wholesale Select 2024 high quality Wet Ball Mills products in best price from certified Chinese Metal Ball manufacturers, Power Ball suppliers, wholesalers and factory on MadeinChina High Efficiency Mining Equipment Ore Wet Grinding Ball Mill US$ 1600070000 / set 1 set (MOQ) Yantai Huize Mining Engineering Co One of Russia's largest ball mill in size 4,6×14 m, with an power installation is 4250 kW [11] when the specific surface of the finished product in 3230 cm2pg reached capacity 126 tphAnalysis of the efficiency of the grinding process in 2024年9月3日 REPLACEMENT OF WET BALL MILLING WITH HIGHPRESSURE GRINDING AHEAD OF MINERAL SEPARATION C Gagnon1, A Rosa1, S Makni1, and *R McIvor1 B Klein2, A Kumar2, F Wang2, D Gong2, and C Saud2 1COREM 1180 rue de la Minéralogie Quebec City, Quebec, Canada G1N 1X7 (*Corresponding author: This address is being REPLACEMENT OF WET BALL MILLING WITH HIGHPRESSURE GRINDING 2024年1月12日 How Overflow Type Ball Mill Works Material Feed: The raw material is fed into the mill at one end and travels through the mill by rotation The feed enters the mill at a specific rate, ensuring a controlled grinding process; Grinding Process: As the mill rotates, the grinding media crushes and grinds the material into a fine powder The wet conditions enhance the Wet Overflow Type Ball Mill and Applications

.jpg)

Factors Affecting Ball Mill Grinding Efficiency 911Metallurgist

2017年10月26日 a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this factor into account As well, mills with different length to diameter ratios for a given power rating will yield different material 2017年9月13日 Operating efficiency, based upon using operating work indices, is also a useful tool in comparing the variations in grinding mill operations such as: mill speed, mill size, size of grinding media, mill discharge arrangements, liner designs etcHow to Calculate Grinding Mill Operating Efficiency2021年5月8日 Kolev et al (2021) –In press Improving the energy efficiency in tumbling mills with the use of Relo grinding media (MDPI) • Lab trials conducted using a standard Bond ball mill (@ Wardell Armstrong) • Standard Bond ball mill procedures were followed –only the RELO media PSD and mass of charge adjusted to match spherical mediaRethinking Grinding Efficiency in Ball Mills RELO 2012年6月1日 Ball mills can grind a wide range of materials, including metals, ceramics, and polymers, and can operate on a variety of scales, from laboratory to industrial (Monov et al 2013) (PDF) Grinding in Ball Mills: Modeling and Process Control

What Are the Differences Between Dry and Wet Ball Mills?

2021年9月10日 How to choose dry and wet ball mill 1 Correctly choose the feeding way of dry grinding and wet grinding Whether feed the material dry or wet depends entirely on the subsequent operations in the ball mill and the nature of the produc Some materials require dry grinding because they will undergo physical or chemical changes after adding waterKeywords: Ball size; Particle size; Powder loading; Rotation speed; Wet ball mill 1 Introduction Wet ball mill is one of the most predominantly used method for the purpose of mixing and grinding of raw materials in laboratories and industry [1–3] The ball mill process is very complicated process governed by many parameters, such as ball Effect of ball size and powder loading on the milling 2024年8月8日 Unlock the secrets to ball mill efficiency with our comprehensive guide on choosing the right grinding media Learn how material composition, size, shape, hardness, and cost impact your milling process and outcomes Ball Mill Success: A StepbyStep Guide to Model PMG series high efficient ball mill have been designed with the merits of open circuit grinding system and important renovations on traditional ball millsBesides they have all the good advantages of open circult mills,production capacity has been raised substantially, product becomes super fine and blains have been increasedIt has provided a new type of grinding Ball millPMG series high efficient ball mill China Pengfei

High Efficiency Mining Equipment Ore Wet Grinding Ball Mil

2024年12月2日 Ball Mill i s composed of a horizontal cylinder, inlet and outlet material hollow shaft and grinding head, the cylinder is a long cylinder, the cylinder is equipped with grinding body, the cylinder is made of steel plate, the lining plate is fixed with the cylinder, grinding body is generally steel ball, and according to different diameters and a certain proportion into the The Planetary Ball mills, the Mixer Mills MM 500 nano and MM 500 control, as well as the High Energy Ball Mill Emax, offer greater versatility compared to Bead Mills All these mills are suitable for both dry and wet grinding Unlike bead mills, RETSCH ball mills can also process larger sample pieces using larger grinding ballsBead Mills for ultrafine grinding RETSCH2024年9月1日 High Efficiency Ore Grinding Plant Wet Ball Milling Machine, Find Details and Price about Ball Mill Ball Mill Machine from High Efficiency Ore Grinding Plant Wet Ball Milling Machine Yantai Huize Mining Engineering Co, LtdHigh Efficiency Ore Grinding Plant Wet Ball Milling MachineWet ball milling has several advantages over dry ball milling Let’s explore some of them: 1 Better Grinding Efficiency The liquid in wet ball milling acts as a lubricant, reducing friction and improving the grinding efficiency The particles are more effectively ground and dispersed, resulting in a finer particle size distribution 2What are the Advantages of Wet Ball Milling?

Wet Ball Mills SolidsWiki

2022年7月7日 Wet Ball Mills are Ball Mills that are used widely in the ore beneficiation industry,as well as the building material industry such as glass During the producing phase, the material and water are mixed together to grind in the ball mill Under the effect of the flowing water,the material will get a better flow ability so the processing capacity will be higherThe proven classical option for cement grinding Whether employed as a twocompartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable alternative for cement and granulated blast furnace slag grinding Used in combination with the sepol® highefficiency separator, ball mills can reliably Ball Mill thyssenkrupp Polysius2023年2月15日 Most of the ball mill types sold on the market are wet ball mills, as they have high grinding fineness and good beneficiation effect As dry and wet ball mills both have their own advantages, we must find out the suitable grinding type to ensure the production quality and efficiency Welcome to consult Fote company, where our professionals will What Are the Differences between Dry and Wet Type Ball Mill?2017年7月3日 Batch Ball Mill Grinding Capacities and efficiencies in wet and dry ball milling at different speeds and ore charges have been discussed in the foregoing pages The results are summarized in table 16, which shows that in both capacity and efficiency grinding was at its best with small ore charges and high speedWet Grinding VS Dry Ball Mill Grinding 911Metallurgist

.jpg)

Exploring the Link between HY Wet Ball Mill Work Index and Grinding

2024年11月11日 In evaluating ore grinding energy consumption using the Bond ball mill work index, discrepancies were identified As a result, an investigation into the determination method of Hou Ying (HY) wet ball milling work index (WHY) for Gongchangling magnetite ore was conducted to determine the correlation between WHY and grinding energy consumption at varying Figure 4 CMM Ball Mill Feed Machine Grinding Rates With and Without Fines (9% Moisture) Thus, Functional Performance Analysis of the highpressure, opencircuit piston press testing provided the major discovery, and also quantified, that grinding efficiency on REPLACEMENT OF WET BALL MILLING WITH HIGH 2023年11月28日 In response to the Natural Resources Canada “Crush It Challenge,” Corem partnered with the University of British Columbia and led a project to develop and demonstrate the use of highpressure grinding to replace the workhorse of the industry, wet ball milling Two plant case studies, a small tonnage gold recovery operation and a large tonnage copper recovery Replacement of Wet Ball Milling with HighPressure Grinding 2024年11月29日 Because the granularity of first stage ball mill is large, the impact force is great, and the wear is serious, so the magnetic liner is generally only suitable for the second stage ball mill Grinding medium of ball mill The grinding medium is essential for the ball mill, and the consumption is very largeHigh Efficiency China Stone Grinder Machine Ball Mill

.jpg)

Ball Mill Grinder Wet Dry Grinding Ball Mill Labotronics

Its robust construction and highspeed capabilities ensure reliable and consistent performance in achieving desired particle sizes Our ball mill grinder's efficiency lies in its ability to convert coarse particles into a uniform, fine powder, making it essential equipment for material refinement and preparation across various industrial 2024年12月12日 In this paper, a new grinding method utilizing impellerdriven particle motions was proposed A discrete element kinetic model for simulating the grinding process of SiO 2 material was established Through the quantitative analysis of energy conversion during grinding, the kinetic energy of particles, the kinetic energy of materials, and the energy consumed by Improving grinding efficiency and performance of new impeller type ball 2023年12月14日 A wet grinding ball mill is a grinding process using a liquid suspension or slurry, providing efficient and effective particle size reduction in wet conditions Skip to content HOME ABOUT US BALL MILL PRODUCTS Close BALL MILL PRODUCTS Open BALL MILL PRODUCTS; BENEFICIATION EQUIPMENT How To Optimize Wet Grinding Ball Mill Performance Wet Ball Mill 2024年4月24日 A ball mill is a crucial type of grinding machine widely employed in various industries for size reduction and material processing So, what is a ball mill? It consists of rotating cylinders filled with grinding balls, which are typically made of steel or ceramicAs the cylinder rotates, the grinding balls collide with the materials, creating both impact and shear forces that What is a Ball Mill? Exploring the Uses and Functionality of Ball Mill

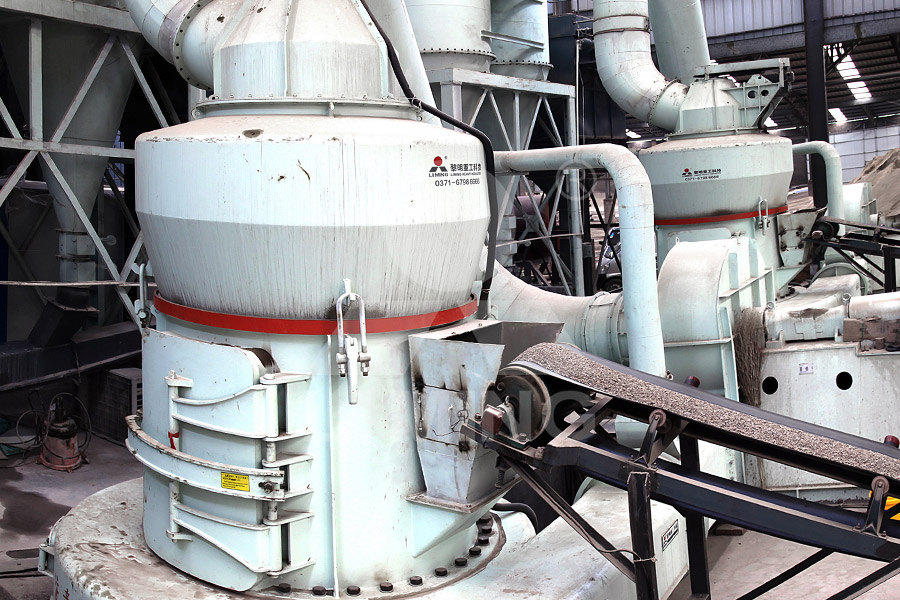

Wet grinding ball mills: An industrial perspective NEWS

2024年9月15日 Wet grinding ball mills are an essential tool in the industrial sector for processing a wide range of materials These mills are designed to grind and mix materials by using rotating balls that are immersed in a liquid medium, typically wa The mills are energyefficient, have a high capacity, and offer easy control of temperature and pH