Antimony Processing Technology

METHODS FOR PROCESSING OF ANTIMONY

2023年6月29日 provides an overview of methods for processing antimonycontaining mineral and technogenic raw materials, as well as methods for refining rough antimony, which is an 2023年6月7日 Antimony metallurgy is the technology that extracts antimony metal from antimony ores or produces antimony compounds Antimony was discovered in the ancient Antimony Metallurgy SpringerLink1989年1月1日 In this article we shall begin by reviewing a number of common types of antimonybearing ores from the standpoint of market demands on concentrates and selective Current processing technology for antimonybearing ores a 2024年3月20日 This article explores the fascinating world of antimony processing, shedding light on its extraction, refining, and applications Understanding the methods and advancements in antimony processing is Antimony Processing: Unlocking the Potential of

.jpg)

Current processing technology for antimonybearing ores a

1989年1月1日 On the basis of knowledge of the beneficiation properties of antimony minerals reported in the previous part of this article, this second half reviews the state of technology for 2022年10月11日 This paper reviews the stateoftheart technologies for the antimony separation and recovery from refractory ores and metallurgical residues The advantages and A review of the technologies for antimony recovery from 2022年1月1日 Antimony usage is gaining importance in several emerging technologies Current technological and market trends of antimony are presented Extractive metallurgy for Stibnite Technological trends, emerging applications and metallurgical 2013年1月1日 Many new technologies that are applied in these traditional antimony smelting processes play important roles, such as deleading agent, antimony white production, air Development of Antimony Smelting Technology in China

Beneficiation of antimony oxide ore: A review Russian

2017年9月7日 Much attention has been paid to improving the mineral processing technology of antimony oxide based on such experiments This work presents the latest research on 2024年3月20日 This article explores the fascinating world of antimony processing, shedding light on its extraction, refining, and applications such as using cleaner technologies and recycling methods 05 Future Trends Back As Antimony Processing: Unlocking the Potential of 2022年10月11日 In this process, antimony was recovered in a single step in the form of cathode antimony (> 98%), thereby resolving the technical problem of antimony and arsenic separation and hence, preventing A review of the technologies for antimony recovery from 2 天之前 How to improve the recovery rate of antimony ore beneficiation? 1 The flotation reagent system is the key to improving the level of mineral processing technology, mainly to find a costeffective collector for antimony oxide ore, Three Methods To Antimony Ore Beneficiation

Nontoxic, nowaste process technology for antimony recovery

2019年9月27日 EUfunded researchers working on the Stibiox project have developed patented ecofriendly process technology to easily recover antimony from a variety of sources Its utility does not end there Along with antimony, the process results in separation and isolation of the other metals with which it is bound, yielding additional marketable compounds1989年1月1日 Current processing technology for antimonybearing ores a review, part 2 Author links open overlay panel T Lager, KSE Forssberg Show more Add to Mendeley Share Cite During processing antimony is mobilized reporting to waste solid tailings or effluent streams This becomes a matter of concern since antimony is similar to arsenic in Current processing technology for antimonybearing ores a 2012年5月19日 A technology has been developed for the hydrometallurgical processing of goldantimony concentrates The technology makes it possible to significantly increase the recovery of antimony and noble metals The final yield of antimony from the scheme that is described for the hydrometallurgical processing of goldantimony concentrates is roughly 80%, the net profit Development of a lowwaste technology for processing 2022年10月11日 Mineral Processing and Extractive Metallurgy Review An International Journal Volume 45, 2024 Issue 3 Submit an article This paper reviews the stateoftheart technologies for the antimony separation and recovery from refractory ores and metallurgical residues The advantages and limitations of these technologies are discussed with A review of the technologies for antimony recovery from

.jpg)

METHODS FOR PROCESSING OF ANTIMONY

2023年6月29日 remove antimony from ores and concentrates containing gold The use of one or another method of processing antimonycontaining ores and concentrates depends on the antimony content in them and its form of location (Table 1) Antimony metallurgy is intended for the production of metallic antimony by pyrometallurgical and hydrometallurgical methodsThe Toowong Process TM is a sustainable hydrometallurgical process for removing arsenic, antimony and other impurities from base metal concentrates Currently many mines have no option but to ship arsenicbearing concentrates to smelters, often on the other side of the world, and incur the associated penaltiesToowong Process™ Core Resources1992年2月24日 antimony ions are freed by the electrowinning cathode process This alIows recycle back to the leach step where the free sulfide solubilizes additional antimony(PDF) Processing of Antimony at the Sunshine Mine2024年11月16日 The cost of an antimony processing plant depends on factors like scale, location, technology, and environmental compliance For small to mediumscale operations, costs can range from $300,000 to $1 million, while larger plants require $1 million or moreWhat is the Cost of Antimony Processing Plant? Mining Pedia

.jpg)

Processing of goldantimony concentrates Request PDF

2021年3月31日 An integrated twostage metallurgical technology has been developed for processing concentrates from the Olimpiadinskoe deposit with high antimony and arsenic content2024年9月2日 Producing such highpurity chemical compounds requires advanced processing technologies, and export controls with this highpurity threshold are likely aimed at restricting the export of high valueadded antimony products and advanced processing technologies These ultrapure products are used in specialised industries, including highend Antimony: The Hidden Metal Fuelling Global Competition2024年12月10日 Mining Technology Tue, Dec 10, 2024, 2:29 AM 2 min read Perpetua Resources said it will explore antimony processing opportunities with Sunshine Silver Mining Refining, amid a trade war Perpetua, Sunshine Silver sign MOU to explore antimony processing WHAT WE DO Xinhai is focused on providing a whole range of services of Mineral Processing EPC (onestop service for mineral processing plant), including mineral testing, engineer design, equipment manufacture, installation commissioning and local training The teams of geologists, mineral processing mechanic experts of Xinhai are traveling around the world with Mineral Processing Plant, Technology, Equipment

.jpg)

Technological trends, emerging applications and metallurgical

2022年1月1日 The high antimony slag from this process was reduced in the furnace by coal Antimony recovery reached 944% after direct reduction with coal (Liu et al, 2014) Padilla et al (2018) reported the results of a study of Sb 2 S 3 treatment from copperrich concentrate in order to remove Sb as an alternative process to the volatilization of antimony2013年2月20日 Summary This chapter contains sections titled: Introduction Stibnite AntimonyGold Ore Jamesonite Antimonial Dust Conclusion and Prospects Acknowledgements Development of Antimony Smelting Technology in China 4th International Symposium on High‐Temperature Metallurgical Processing Wiley Online LibraryDevelopment of Antimony Smelting Technology in ChinaIntroduce Antimony Slag Processing Antimony smelting slag is the waste slag discharged in the smelting process, as these slags contain a certain amount of antimony metal, the recovery of which can not only reduce the waste of resources, but also create very considerable economic benefits, so there are many customers invest in the recycling industry of antimony smelting slagAntimony Slag Processing Line Henan Forui Machinery Technology 2022年11月1日 Antimony is of high importance for a wide range of products Its main applications are as a flame retardant in electrical and electronic equipment and textiles, in alloys (leadacid batteries), wires and cables, ceramics, and glass (Tercero Espinoza et al, 2018)In addition, there are some future technologies related to the energy transition in which antimony Resilience in the antimony supply chain ScienceDirect

.jpg)

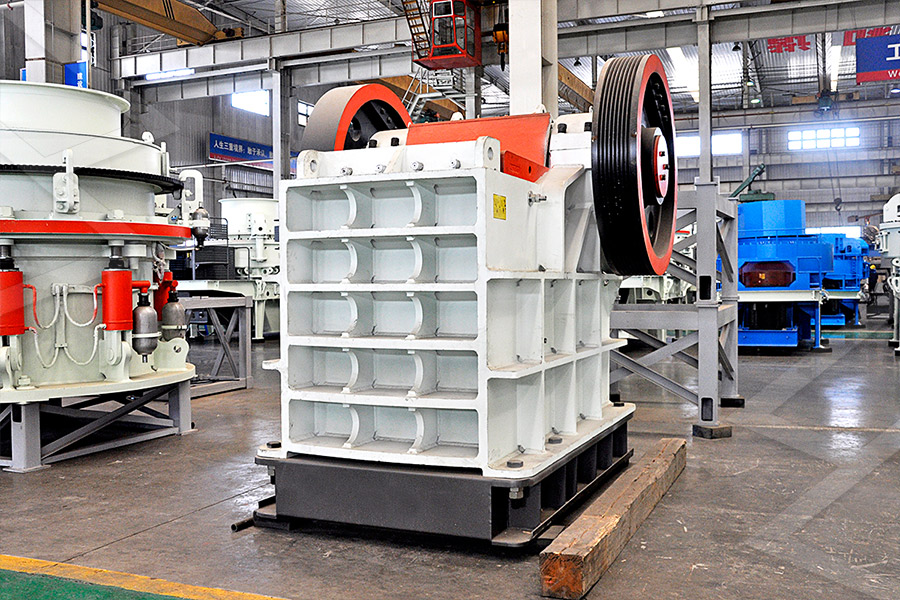

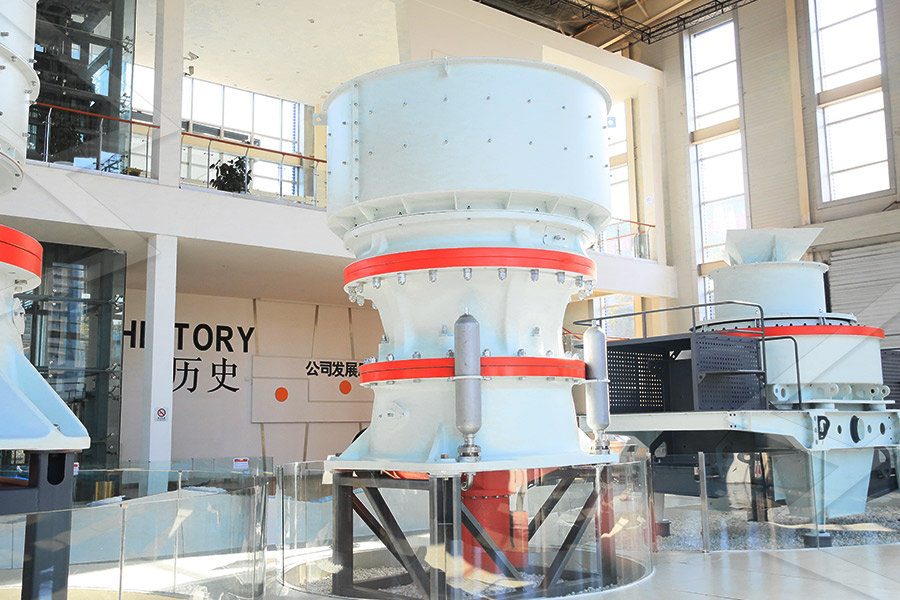

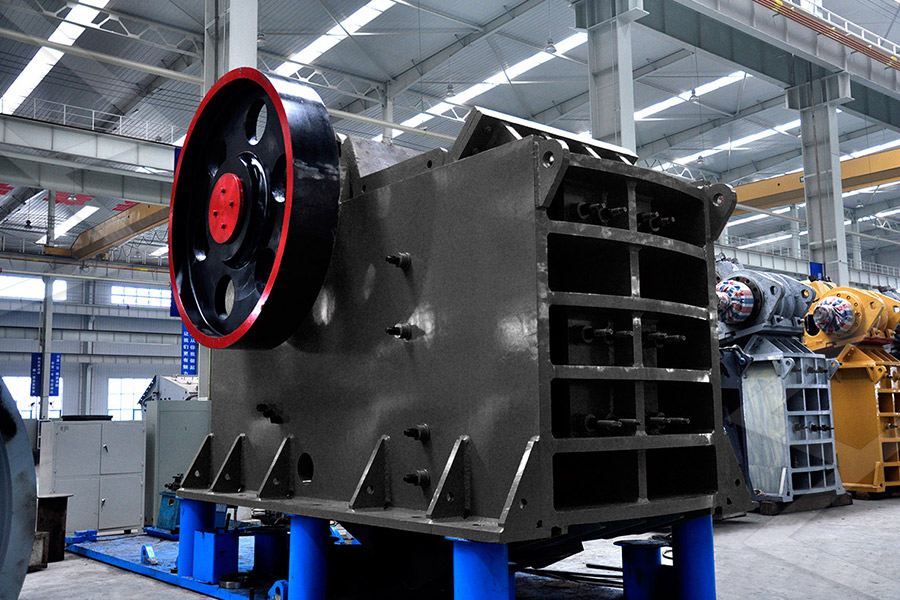

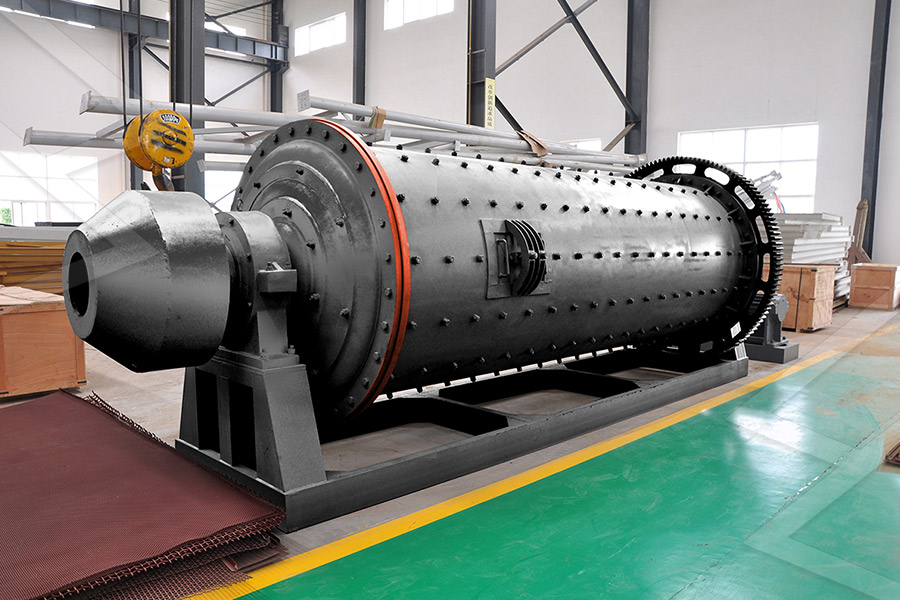

Antimony Ore Processing Line Henan Forui Machinery Technology

Yunnan antimony ore beneficiation production line Stibnite Beneficiation Plant in Yunnan The antimony ore of Yunnan customer is low grade sulphideoxidation syngenetic antimony ore, the original ore grade is 35% The production line adopts jaw crusher, rod mill, jig machine, dewatering screen and other equipmentSemantic Scholar extracted view of "Current processing technology for antimonybearing ores a review, part 2" by T Lager et al Skip to search form Skip to main content Skip to account menu Semantic Scholar's Logo 222,174,243 papers from all fields of science Current processing technology for antimonybearing ores a 2021年8月1日 Antimony is used in many industries and is indispensable This review has brought out the recent developments on antimony removing materials and industry specific antimony treatment technologies The environmental hazards or challenges that arise during the manufacturing processes and applications involving antimony need process specific approachAntimony, a pollutant of emerging concern: A review on 2013年12月27日 Techniques for the processing of antimonybearing ores encompass a wide range of techniques from traditional hand sorting, which is dependent on plentiful and cheap labour, to technologically advanced, capitalintensive mineral processing The main antimony products in international trade are stibnite and subordinate stibniteberthierite and Antimony Critical Metals Handbook Wiley Online Library

.jpg)

Biotechnology of Concentrate and Antimony Ore Processing

The results are presented for using microorganisms for mercury and antimony separation and extraction of oxidized antimony minerals The problems on technology of direct processing of goldantimony concentrates by pentachlorous antimony chlorides are considered The perspective is shown for leaching antimony by alkaline solution of sulfatereducing bacteria The 2024年11月28日 Spearmint Resources noted that the George Lake South Antimony Project is situated near the historic Lake George Antimony Mine, which was North America’s largest primary antimony producer from 1876 until its closure in 1996 The proximity to a former major production site suggests potential for the newly acquired projectSpearmint acquires George Lake South Antimony Project in 2024年12月10日 John Paulsonbacked Perpetua Resources has agreed to work with Sunshine Silver Mining Refining Co to find ways within the US to process antimony, one of the critical minerals under China’s Paulsonbacked Perpetua strikes antimony pact to blunt 2024年12月5日 On Tuesday, December 3, China announced stringent export restrictions on “dualuse” technologies for both civilian and military use, specifically targeted at the United States These restrictions double down on previously announced controls on these metals, going so far as to ban shipments of antimony, gallium, and germanium to the United StatesChina Imposes Its Most Stringent Critical Minerals Export

.jpg)

Metallogenic characteristics and resource potential of antimony

2021年11月1日 Antimony deposits have multiple sources of oreforming metals and fluids, of which Precambrian basement strata may be one of the most important China has a long mining history of Sb exploration, due to its good mining conditions and highlevel mineral processing technology that allow the metal Sb be efficiently extracted from Sb ores A 2023年10月1日 Other technological efforts, such as updating of production equipment, more sophisticated and efficient dressing smelting process, and innovative design and disassembling technologies, can further improve antimony resource efficiency (Deng et al, 2021) In addition, research efforts should be made to promote the application of antimony in the Dynamic material flow analysis of antimony resources in China2024年11月6日 Antimony is a fifthperiod element in the nitrogen family, a silverwhite metalloid with weak conductivity and thermal conductivity It is stable at room temperature and does not react easily with oxygen and water in the air Natural minerals are found in the form of sulfides Current research and applications are mostly concentrated on material modification, utilizing Applications of Antimony in Catalysis ACS Organic2024年3月20日 This article explores the fascinating world of antimony processing, shedding light on its extraction, refining, and applications such as using cleaner technologies and recycling methods 05 Future Trends Back As Antimony Processing: Unlocking the Potential of

.jpg)

A review of the technologies for antimony recovery from

2022年10月11日 In this process, antimony was recovered in a single step in the form of cathode antimony (> 98%), thereby resolving the technical problem of antimony and arsenic separation and hence, preventing 2 天之前 How to improve the recovery rate of antimony ore beneficiation? 1 The flotation reagent system is the key to improving the level of mineral processing technology, mainly to find a costeffective collector for antimony oxide ore, Three Methods To Antimony Ore Beneficiation 2019年9月27日 EUfunded researchers working on the Stibiox project have developed patented ecofriendly process technology to easily recover antimony from a variety of sources Its utility does not end there Along with antimony, the process results in separation and isolation of the other metals with which it is bound, yielding additional marketable compoundsNontoxic, nowaste process technology for antimony recovery1989年1月1日 Current processing technology for antimonybearing ores a review, part 2 Author links open overlay panel T Lager, KSE Forssberg Show more Add to Mendeley Share Cite During processing antimony is mobilized reporting to waste solid tailings or effluent streams This becomes a matter of concern since antimony is similar to arsenic in Current processing technology for antimonybearing ores a

Development of a lowwaste technology for processing

2012年5月19日 A technology has been developed for the hydrometallurgical processing of goldantimony concentrates The technology makes it possible to significantly increase the recovery of antimony and noble metals The final yield of antimony from the scheme that is described for the hydrometallurgical processing of goldantimony concentrates is roughly 80%, the net profit 2022年10月11日 Mineral Processing and Extractive Metallurgy Review An International Journal Volume 45, 2024 Issue 3 Submit an article This paper reviews the stateoftheart technologies for the antimony separation and recovery from refractory ores and metallurgical residues The advantages and limitations of these technologies are discussed with A review of the technologies for antimony recovery from 2023年6月29日 remove antimony from ores and concentrates containing gold The use of one or another method of processing antimonycontaining ores and concentrates depends on the antimony content in them and its form of location (Table 1) Antimony metallurgy is intended for the production of metallic antimony by pyrometallurgical and hydrometallurgical methodsMETHODS FOR PROCESSING OF ANTIMONY The Toowong Process TM is a sustainable hydrometallurgical process for removing arsenic, antimony and other impurities from base metal concentrates Currently many mines have no option but to ship arsenicbearing concentrates to smelters, often on the other side of the world, and incur the associated penaltiesToowong Process™ Core Resources

(PDF) Processing of Antimony at the Sunshine Mine

1992年2月24日 antimony ions are freed by the electrowinning cathode process This alIows recycle back to the leach step where the free sulfide solubilizes additional antimony