Coal Mill Working Princle How To Shovel On A Conveyor Belt Coal Mining

.jpg)

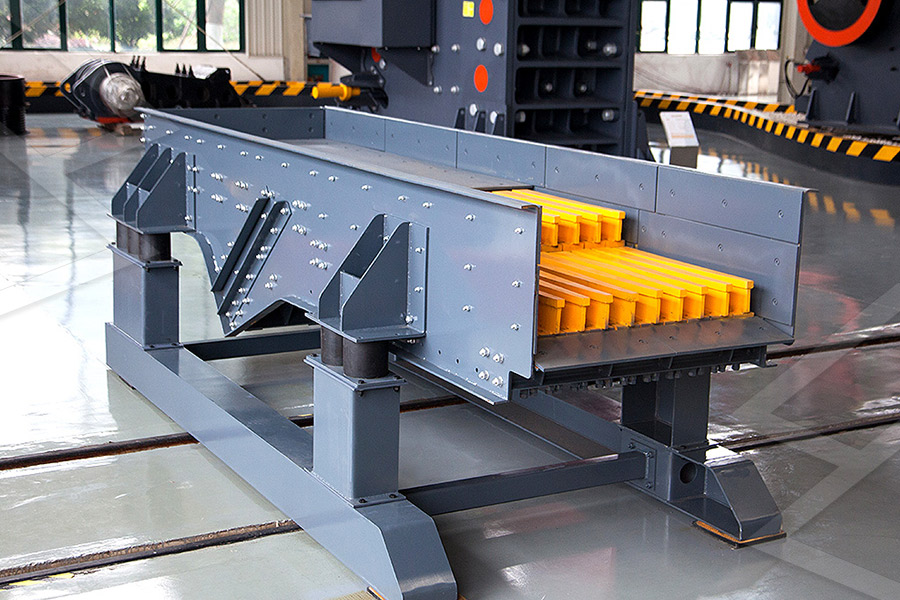

Coal Mining Conveyor Belt: What is it and How to Make it

2024年10月14日 Coal mining conveyor belts are essential tools in the mining industry, designed specifically to transport coal efficiently from the extraction site to processing facilities or 2018年4月27日 7 Construction and Maintenance of Belt Conveyors for Coal and Bulk Material Handling Plants practicalmaintenance Material Classification and Codification Construction and Maintenance of Belt Conveyors for 2021年7月14日 Various belt conveyors are provided for transporting the coal from Track hopper to Bunkers In order to ensure the continuous and stable operation of the belt conveying Operation of Belt Conveyors in Coal Handling Plant2024年3月13日 Choosing the Right Conveyor Belt for the Coal Mining Industry Selecting the appropriate coal mining conveyor belt is pivotal for ensuring operational efficiency, safety, and longevity in the harsh conditions of the How to Select Coal Mining Conveyor Belt Systems

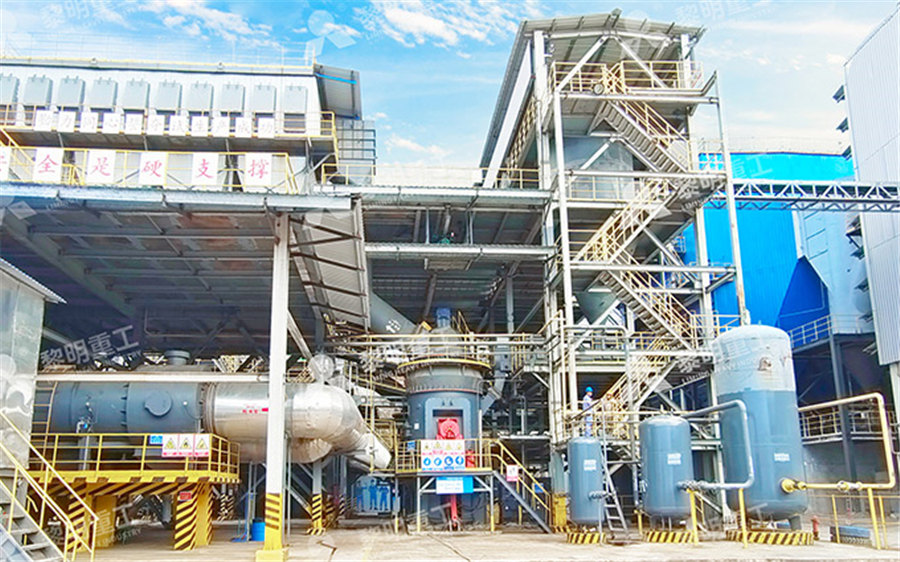

How does a coal mill work? zenithmineral

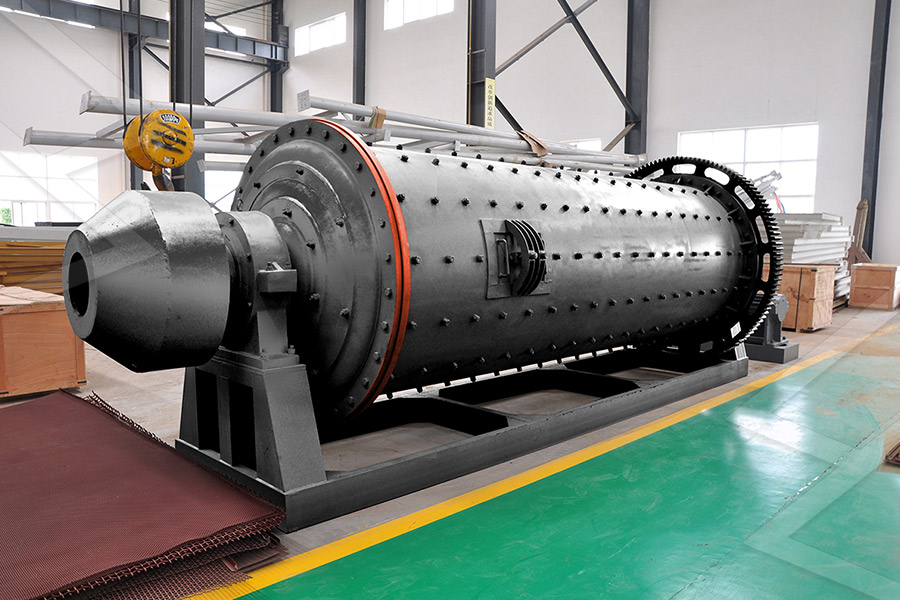

A coal mill, also known as a pulverizer, is used to grind coal into a fine powder for use in thermal power plants Here's a general outline of how it works: Raw Coal Inlet: Raw coal from the coal 2021年8月5日 A conveyor system work by using two pulleys that continuously loop over the material that rotates over them the belt is then supported by a series of rollers along the path DESIGN, ANALYSIS AND OPTIMISATION OF BELT 2016年1月8日 Study and Design of Belt Conveyor System in Coal Mines has been written as a part of work and also to foster the use as a handbook for general applications in coal minesStudy and Design of Belt Conveyor System in Coal Mines2013年1月1日 This chapter discusses the possibilities of the use of materials handling machines for coal applications It gives an overview on conveying, storing, loading/unloading and Coal handling along the supply chain ScienceDirect

.jpg)

(PDF) Coal Transport Through The Conveyor Belt: Literature

Transportation through sea transportation modes can be carried out to the side of the port and transported further by trucking mode or by other transportation systems, namely using a 2024年12月17日 Troughed belt conveyors are used prolifically throughout the mining industry, carrying ores, concentrates, and tailings throughout every stage of the mining cycle, from initial excavation, through beneficiation, to the Belt Conveyors in the Mining Industry FEECO 2024年3月19日 Coal handling plays a pivotal role in the efficiency and sustainability of various industries, most notably in thermal power plants and coal mining operations belt conveyor system for coal handling transport large Belt Conveyor System for Coal Handling in a 2024年4月2日 The formula to calculate the capacity of a conveyor belt in tons per hour is: [{Capacity (tons per hour)} = {{{Belt Speed (m/s)} × {Belt Width (m)} × {Material Density (kg/m}^3} × {Belt Load (m)}} ÷ {{1000 × 3600}}] Where: Belt How to Calculate Tons Per Hour Conveyor Belt

Detecting Water and Coal Ore on a Conveyor Belt

We used a 20kHz acoustic transducer directly over the top of the conveyor, to detect a presence or absence of material on the belt To detect the difference between water and coal (solids), we used a very low frequency 10kHz acoustic transducer, mounted on a 60 degree angle aimed at the trough (bottom) of the conveyor beltA simple energy balance model of the coal mill is derived in (Odgaard and Mataji 2006), this model is based on a more detailed model found in (Rees and Fan 2003)In this model the coal mill is seen as one body with the mass m mThe following variables are defined: T(t) is the temperature in the coal dust flow in the mill, ṁ PA (t) is the primary air mass flow, T PA (t) is Coal Mill an overview ScienceDirect Topics2022年3月17日 The belt conveyor is the most commonly used conveying equipment in the coal mining industry As the core part of the conveyor, the belt is vulnerable to various failures, such as scratches, cracks (PDF) Belt Tear Detection for Coal Mining Conveyors2021年4月12日 This explains why conveyors look like they do and where they fit into a number of business processes The Belt If the function of a conveyor belt is transportation, the vehicle of this process is the belt itself A looped part of the overall conveyor machine, the belt is regularly made of metal – and sometimes of linked metal chainsHow Do Conveyor Belts Work: A Comprehensive Guide

.jpg)

Safety: recognize hazards to prevent conveyorrelated injury

2020年5月21日 As such, a conveyor presents enough danger zones that the entire system should be considered a hazard The belt In most applications, a conveyor belt moves at a relatively constant speed, commonly running somewhere between 05 and 10 meters per second [≈100 to 2000 fpm]2020年4月14日 Conveyor Belt Group 6 1 2 3 Flowchart of mining, processing, combustion of coal and further utilisation or disposal of fly ash at a mining and power plant company Coal mining conveying Short long distance conveying between mine and power plant Coal stockpiling transportation in front of/ to the power plantConveyor Belt Solutions for every mining task2020年12月3日 Holding conveyor costs down and improving uptime adds to the bottom line by steve fiscor, editorinchief Conveyors serve as the arterial system for coal mines and prep plants Longwalls and continuous miner sections are often limited by conveyor capacity and availability Likewise, prep plants rely on conveyors to deliver raw coal and to transport clean []Fresh Approaches for Coal Conveyors2024年3月12日 alternating sandwich belt conveyors Such ambitious multiflight systems as described above are yet to be realized but single flight vertical sandwich belt high angle conveyors, the basis for these systems, were commercially utilized at vertical shafts from underground coal mining, gypsum mining and tunneling projects The most impressive theseSandwich Belt High Angle Conveyors Coal Mine to Prep

.jpg)

How to Calculate the Quantity of a Conveyor Belt on a Roll

2017年9月26日 Determine the gauge, or thickness, of your conveyor belt Belt gauges generally run from between 01 inches to 13 inches, depending of the application You can either measure directly or ask your belt manufacturer for the belt specifications For example, you might have a belt that is 05 inches thick2024年6月9日 The coal conveyor system is a vital component in various industries, ensuring the efficient and safe transport of coal Coal conveyor system for coal ports and power plants, efficiently transport large quantities of coal What is the Coal Conveyor System2012年5月1日 Coal fired power plants are heavily used due to large and long lasting coal resources compared with oil or natural gas An important bottleneck in the operation of this particular kind of plants, however, is the coal pulverization process, which gives rise to slow takeup rates and frequent plant shutdowns (Rees Fan, 2003)In typical coal fired power plants, Derivation and validation of a coal mill model for control2021年4月1日 The conveyor belt, as an important part of the belt conveyor, plays a role in carrying materials and transferring power, and its cost accounts for 30%–50% of the total cost of the conveyor [13]Conveyor belts often suffer longitudinal tearing, surface scratches, and other damage when the rollers are broken or the material is jammed [14]If not detected or dealt with Deep learningbased damage detection of mining conveyor belt

.jpg)

(PDF) Failure analysis of belt conveyor systems ResearchGate

2009年1月1日 The belt conveyor (BC) is the main means of horizontal transportation of bulk materials at mining sites The sudden fault in BC modules may cause unexpected stops in production lines2024年6月5日 Conveyor belts play a critical role in coal mining operations, serving as an essential component in the transportation of coal A coal mine conveyor belt is designed to efficiently move large quantities of coal from the mining site to processing facilities, reducing the need for manual labor and enhancing overall operational efficiencyCoal Mine Conveyor Belt Systems Choose and PurposeFenner Dunlop produces the highest quality fire retardant, straight warp, steel cord, and premium plied belting for all underground and surface applications Fenner Dunlop straight warp, belts, like MineFlex, are used extensively in underground mines for the extraction of both thermal coal and coking coal MineFlex is also great for above ground applications like coalfired []Coal Mining – Fenner Dunlop Conveyor Belting2022年1月18日 How to Choose the Right Industrial Conveyor System Before deciding on what type of conveyor system is right for your application, there are three major factors to consider: Material: This is the most crucial consideration when choosing a conveyor belt system Think about the size, moisture content and whether the material you are moving flows or is How Does a Conveyor Belt Work? Span Tech Conveyors

.jpg)

Tech Guide: Mining Conveyor Belt Metal Detector Features

2024年3月15日 Mining operations are complex environments where safety and efficiency are paramount The introduction of a mining conveyor belt metal detector has significantly enhanced these aspects by providing a reliable means of detecting harmful metals embedded in the conveyed material These sophisticated devices are crucial in identifying and removing 2016年2月14日 there were 1356 km of belt conveyors install ed in British coal mines in 1948 which rose to 2692 km by 1953 A typical presentday large coal mine has so me 30 km of belt conveyors(PDF) COAL MINING METHODS ResearchGate2021年8月26日 Tip 3: Protect the conveyor belt by preparing for impact with impact beds Located underneath the belt in the load zone, impact/slider beds offer conveyor belt protection and material containment by controlling Combatting Belt Conveyor Spillage: How to 2024年5月3日 In the realm of belt conveyor chute design, the Chute Design Handbook PDF and Transfer Chute Design Manual PDF serve as indispensable resources for engineers and operatorsThese documents offer comprehensive Belt Conveyor Chute Design: How to Design and

.jpg)

Study and Design of Belt Conveyor System in Coal Mines

2016年1月8日 Study and Design of Belt Conveyor System in Coal Mines has been written as a part of work and also to foster the use as a handbook for general applications in coal mines Mining Industry in India 2024年3月14日 The role of an underground coal mining conveyor belt extends beyond the confines of the mine itself, playing a pivotal role in the operation of thermal power plants These conveyor systems are critical for the continuous, efficient, and safe supply of coal to power generation facilities, ensuring a steady production of electricity to meet the Innovations in Underground Coal Mining Conveyor Belt FLS is a leading, full flowsheet minerals processing supplier to the global mining industry We deliver proven technologies and services across the lifecycle of operations, and have set targets of providing solutions for zeroemissions mining by 2030 with our MissionZero programmeFLS Empowering the future of mining FLSmidth6 天之前 These conveyor systems must integrate seamlessly into the entire operation while operating reliably and effectively West River Conveyors will provide you with a turnkey coal conveyor system that fits perfectly into your processes We have decades of experience working with coal companies to custombuild the perfect conveyor system for various Coal Conveyor Belt Systems West River Conveyors

Online Analysis of Coal on A Conveyor Belt by use of

2010年11月1日 Aiming at the problem that mining conveyor belts are easily damaged under severe working conditions, based on the reclassification and definition of conveyor belt damage types, a special data set This method recovers a higher proportion of the coal deposit than underground mining as all coal seams are exploited – 90% or more of the coal can be recovered Large opencast mines can cover an area of many square kilometres and use very large pieces of equipment, such as draglines, power shovels, large trucks, bucket wheel excavators and Coal Industry – ASGCO2019年4月11日 PBE’s mining conveyor belt monitoring devices can be used as part of a holistic safety system PBE’s BeltBoss monitoring solutions can be used as standalone devices of or be networked into the operation’s central system through the MineBoss™ 20 and monitored from the surface control centreMining conveyor belts: Why effective monitoring is essential2024年12月17日 Troughed belt conveyors are used prolifically throughout the mining industry, carrying ores, concentrates, and tailings throughout every stage of the mining cycle, from initial excavation, through beneficiation, to the Belt Conveyors in the Mining Industry FEECO

.jpg)

Belt Conveyor System for Coal Handling in a

2024年3月19日 Coal handling plays a pivotal role in the efficiency and sustainability of various industries, most notably in thermal power plants and coal mining operations belt conveyor system for coal handling transport large 2024年4月2日 The formula to calculate the capacity of a conveyor belt in tons per hour is: [{Capacity (tons per hour)} = {{{Belt Speed (m/s)} × {Belt Width (m)} × {Material Density (kg/m}^3} × {Belt Load (m)}} ÷ {{1000 × 3600}}] Where: Belt How to Calculate Tons Per Hour Conveyor BeltWe used a 20kHz acoustic transducer directly over the top of the conveyor, to detect a presence or absence of material on the belt To detect the difference between water and coal (solids), we used a very low frequency 10kHz acoustic transducer, mounted on a 60 degree angle aimed at the trough (bottom) of the conveyor beltDetecting Water and Coal Ore on a Conveyor BeltA simple energy balance model of the coal mill is derived in (Odgaard and Mataji 2006), this model is based on a more detailed model found in (Rees and Fan 2003)In this model the coal mill is seen as one body with the mass m mThe following variables are defined: T(t) is the temperature in the coal dust flow in the mill, ṁ PA (t) is the primary air mass flow, T PA (t) is Coal Mill an overview ScienceDirect Topics

(PDF) Belt Tear Detection for Coal Mining Conveyors

2022年3月17日 The belt conveyor is the most commonly used conveying equipment in the coal mining industry As the core part of the conveyor, the belt is vulnerable to various failures, such as scratches, cracks 2021年4月12日 This explains why conveyors look like they do and where they fit into a number of business processes The Belt If the function of a conveyor belt is transportation, the vehicle of this process is the belt itself A looped part of the overall conveyor machine, the belt is regularly made of metal – and sometimes of linked metal chainsHow Do Conveyor Belts Work: A Comprehensive Guide2020年5月21日 As such, a conveyor presents enough danger zones that the entire system should be considered a hazard The belt In most applications, a conveyor belt moves at a relatively constant speed, commonly running somewhere between 05 and 10 meters per second [≈100 to 2000 fpm]Safety: recognize hazards to prevent conveyorrelated injury2020年4月14日 Conveyor Belt Group 6 1 2 3 Flowchart of mining, processing, combustion of coal and further utilisation or disposal of fly ash at a mining and power plant company Coal mining conveying Short long distance conveying between mine and power plant Coal stockpiling transportation in front of/ to the power plantConveyor Belt Solutions for every mining task

.jpg)

Fresh Approaches for Coal Conveyors

2020年12月3日 Holding conveyor costs down and improving uptime adds to the bottom line by steve fiscor, editorinchief Conveyors serve as the arterial system for coal mines and prep plants Longwalls and continuous miner sections are often limited by conveyor capacity and availability Likewise, prep plants rely on conveyors to deliver raw coal and to transport clean []